Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

Flame retardant and high temperature resistant media help keep people and property safe from fire. The table below shows the main definitions and standards for these materials in industry:

| Term/Concept | Definition/Description | Relevant Industrial Standards |

|---|---|---|

| Flame Retardant Media (FR) | Materials made to stop fires from starting and put themselves out. They protect against fire and heat. | NFPA 2112, NFPA 70E, ASTM F1506, ISO 11612, ISO 11611 |

| Inherent FR Fabrics | Fibers that are always flame resistant because of how they are made. Their flame resistance lasts forever. | Used in protective clothing that meets NFPA 2112, NFPA 70E, ASTM F1506, ISO standards. |

| Treated FR Fabrics | Fabrics that get a chemical treatment to resist flames. They work well against fire, hot metal, and electric arcs. | Used in jobs with lots of sparks or hot metal. They meet NFPA 2112, NFPA 70E, ASTM F1506. |

| High Temperature Resistant Media | Fabrics made to handle very high heat and thermal dangers. They often have flame retardant features too. | Standards like ISO 11612 and ISO 11611 show how well they protect during welding and hot metal work. |

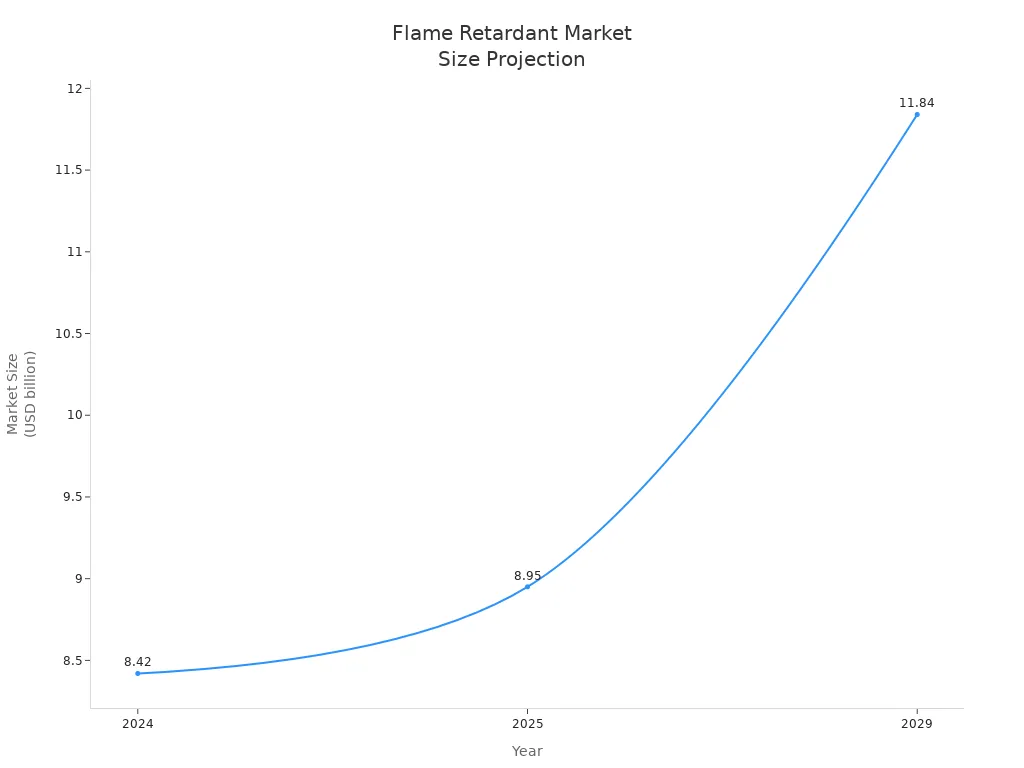

Flame retardant technology helps slow down or stop fire from spreading. High temperature resistant media let materials survive very high heat. Both are important in building, electronics, and transportation. Stronger fire safety rules and new ideas help this market grow, as shown below:

Flame retardant media are made to slow or stop fire. Makers add special chemicals called flame retardants to these materials. These chemicals can be halogenated compounds like bromine and chlorine. Some are inorganic, such as magnesium hydroxide and aluminum hydroxide. Other coatings use phosphorus or nitrogen-based compounds. These help make a shield when the material gets hot.

Flame retardant coatings go on wood, fabrics, plastics, and building stuff. These coatings stop burning by breaking up the fire’s chemical reactions. They can also make a char layer that protects what is underneath. For example, flame retardant MDF has additives like aluminum trihydrate and zinc borate. These help the board swell less and stay strong after heat.

Common flame retardant materials include:

Halogenated hydrocarbons, which slow burning by releasing active atoms.

Inorganic flame retardants, which soak up heat and make a shield.

Nitrogen-based compounds, which help make char and block oxygen.

Intumescent coatings, which get bigger when hot to protect surfaces.

Phosphorus-containing compounds, which make char and stop flammable gases.

Flame retardant and high temperature resistant media use these coatings and additives. This helps them meet tough fire safety rules in construction, electronics, and transportation.

High temperature resistant media can handle very high heat. They do not lose their shape or strength. These materials do not always have flame retardants. They resist heat because of how they are made. High temperature protection is needed in power plants, planes, and factories.

Some common high temperature resistant media are:

Metals and alloys like tungsten, molybdenum, and nickel-based superalloys. These can take heat above 2000°C. They are used in turbines, engines, and reactors.

Ceramics like silicon carbide and alumina. These are stable in heat and used in cutting tools and electronics.

Composites such as carbon/carbon and ceramic-based aerogels. These are light and strong at high heat. They are used in spacecraft and insulation.

Polymers like polyimide and PEEK. These can take heat up to 500°C. They are used in cars and airplanes.

Smart materials, like shape memory alloys, can go back to their shape after heating.

Heat resistant coatings, like ceramic or silica-based layers, are put on metals and composites. These coatings help protect surfaces from heat damage.

Flame retardant and high temperature resistant media have different jobs. Both help with fire safety. Flame retardant media use chemicals or coatings to slow or stop burning. These chemicals break up fire reactions or make a barrier. Flame retardant materials give short-term protection. This gives people more time to escape a fire.

High temperature resistant media are made to last in extreme heat. They do not always have flame retardants. Their structure lets them keep their strength and not burn. Fire-resistant materials like ceramics and superalloys are used for long-lasting protection. They are found in building supports or firefighter gear.

| Aspect | Flame Retardant Media | High Temperature Resistant Media |

|---|---|---|

| Main Function | Slow or stop fire spread using chemicals | Withstand high temperatures and maintain strength |

| How They Work | Use flame retardant coatings or additives | Rely on natural heat resistance and structure |

| Typical Use | Temporary fire protection for evacuation | Long-term fire resistance in harsh environments |

| Examples | Treated fabrics, MDF, plastics with flame retardants | Metals, ceramics, composites, heat resistant coatings |

| Duration of Protection | Limited, slows fire progression | Prolonged, prevents structural failure |

Flame retardant and high temperature resistant media are both important for fire safety. Flame retardant materials stop fires from spreading fast. Fire-resistant materials give lasting protection from high heat. Flame retardant coatings are used in many products. Heat resistant coatings and fire-resistant materials are needed in places with extreme heat.

Note: Some flame retardants can be bad for health and the environment. They may not break down and can build up in living things. Newer flame retardant coatings and materials try to be safer and better for the environment.

Flame retardant media use science to slow or stop fire. These materials work in both solid and gas forms. They mess with the chemical reactions that keep fire going. The chemicals let out things that block flame radicals like H, OH, and O. The timing of this is very important. The additives must act when heat starts to break down the material. This makes sure the flame retardant is there to stop the fire.

Flame retardants work in four main ways:

Intumescence: They make a thick char layer on top. This layer blocks heat and oxygen. It keeps the fire from spreading.

Gas phase inhibition: Some flame retardants let out chemicals that fight the fire’s radicals. This lowers the number of radicals and slows burning.

Endothermic degradation: The flame retardant soaks up heat as it breaks down. This cools things down and makes it harder for fire to grow.

Gas phase dilution: Some flame retardants let out gases like nitrogen or carbon dioxide. These gases mix with the air and make it harder for fire to keep burning.

Tests show that flame retardant materials like polymer composites get better at handling heat and making a char. For example, ammonium polyphosphate makes a carbon layer that blocks burning. Phosphorus-based flame retardants also stop burning in the gas phase. Tests like UL-94 and LOI show these materials can even put themselves out after catching fire.

Fire resistant media that handle high heat use different tricks. These materials depend on their structure and what they are made of. Metals and alloys, like steel with molybdenum and niobium, have special structures inside. These changes make it harder for the metal to bend when hot. High-entropy alloys use solid solution hardening to stay strong in heat.

Other fire resistant materials, like ceramics and composites, fight heat because of their strong chemical bonds. In living things, heat shock proteins help protect cells from heat. Antioxidants lower damage from reactive oxygen species. Some fungi change shape or genes to live through high heat.

These tricks help fire resistant media keep their shape and strength when hot for a long time. This makes them good for power plants, engines, and safety gear.

Scientists test flame retardant and fire resistant media in labs. They check how long a material can avoid catching fire, how far the char goes, and how fast flames move. The table below shows some common tests:

| Test Method | Description / Typical Criteria |

|---|---|

| Flame Retardation Time | Measures how long material resists ignition, up to 60 seconds |

| Char Length | Length of charred material after burning, shorter is better |

| Rate of Flame Spread | Speed at which flame spreads, usually under 30 mm/s |

| UL 94 Horizontal Burn | Flame spread less than 3 inches/min or stops before 5 inches |

| UL 94 Vertical Burn | Flame stops within 10 seconds after two 10-second flame applications |

| Smoke Density Test | Measures smoke opacity; minimum 60% light transmittance required |

Lab studies show that flame retardant media, like those with phosphorus or halogenated compounds, can stop fires by making a char or catching fire radicals. Real events, like wildfires and house fires, show why we need strong flame retardant and fire resistant materials. These materials help protect people and buildings by slowing fire and keeping things safe.

Flame retardant coatings help stop or slow down fire. These coatings use flame retardants like brominated, phosphorus, nitrogen, chlorinated, and inorganic compounds. Each type works in its own way. Brominated and chlorinated types let out atoms that block flames. Phosphorus types help make a char layer. Nitrogen types cool things by letting out gas. Inorganic types, like aluminum trihydrate, make a shield and give off water vapor.

| Type of Flame Retardant | Chemical Characteristics and Mechanism | Common Industry Applications |

|---|---|---|

| Brominated | Release bromine radicals to stop fire in the gas phase | Textiles, electronics, plastics, building materials |

| Phosphorus | Release phosphoric acid to make char and stop burning | Furniture, TV casings, textiles, plastics |

| Nitrogen | Release nitrogen gas to cool and dilute oxygen | Insulation, electronics, furniture foams |

| Chlorinated | Inhibit flame formation, stable at high heat | Polyurethane foam, rubber, plastics |

| Inorganic | Form protective layers, release water vapor | Paints, plastics, insulation, rubber |

Many jobs use flame retardant coatings. Construction puts them on pipes and cables. Electronics need them for circuit boards and wires. Car makers use them inside cars and near batteries. Textiles and furniture also use these coatings for safety.

Flame retardant coatings come in different types. Some are water-based, solvent-based, halogen-free, or phosphate and alumina-based. Water-based types are better for the environment. Solvent-based coatings last longer outside. Halogen-free coatings do not make toxic gases. Phosphate and alumina-based coatings work well in planes and electronics.

Heat resistant coatings keep surfaces safe from very high heat. These coatings use things like silicone, ceramic, metal, epoxy, polyester, fluoropolymers, phenolic, alkyd, and powder coatings. Each type works at different temperatures and has special uses.

| Coating Type | Typical Temperature Range | Key Characteristics and Applications |

|---|---|---|

| Silicone-based | 225°F (107°C) and above | Flexible, used in machinery, exhausts |

| Ceramic-based | Over 1000°C (1832°F) | Great insulation, used in cars, industry, aerospace |

| Metal-based | High, less than ceramic | Strong, used where durability matters |

| Epoxy | Moderate | Resists chemicals, used in factories |

| Polyester powders | Moderate | Durable, resists UV and corrosion |

| Fluoropolymers | Moderate to high | Resists chemicals, used in buildings, cookware |

| Phenolic | Good heat and chemical resistance | Used in industry |

| Alkyd-based | Lower than silicone | Cost-effective for moderate heat |

| Powder coatings | Can exceed 1000°C | Used for extreme heat and durability |

Heat resistant coatings protect engines, pipes, and machines. They help surfaces last longer and stop heat damage.

Flame retardants can be part of the material or added later. Inherent flame retardant materials have protection built in. These materials stay safe even after washing or use. Firefighter suits use these permanent flame retardants. Treated fabrics or coatings add flame retardants after making the fabric. These can wear off with time.

| Feature | Inherent Flame Retardant Materials | Flame Retardant Coatings (Post-Finished) |

|---|---|---|

| Origin | Built into fiber structure | Applied as surface coating or treatment |

| Durability | Permanent, does not wash out | Can wear off with washing or friction |

| Mechanism | Stable chemical structure | Forms barrier or releases gases |

| Comfort and Safety | Softer, safer, lasts longer | May feel rough, can have chemical risks |

| Cost | Higher | Lower, good for mass use |

| Typical Applications | Firefighter gear, aerospace, industry | Curtains, furniture, low-cost clothing |

Flame retardant materials include fabrics, plastics, glues, and compounds. Fire-resistant materials like ceramics and superalloys also protect against heat. Both fire-resistant and flame retardant coatings help, but inherent flame retardant materials last longer. Flame retardants in glues and compounds help keep electronics and buildings safe.

Note: Inherent flame retardant fabrics protect longer, but treated or coated fabrics cost less and are good for making many items. Both types are important for fire safety.

Flame retardant and high temperature resistant media are very important in building. Builders use them for insulation, pipes, wire covers, and roofs. The table below lists where these materials are used and what protects them from fire:

| Application Area | Examples of Materials/Products | Flame Retardant Additives / Features |

|---|---|---|

| Insulation | EPS, XPS, polyurethane foams | Polymeric FRs, Tetrabromobisphenol-A, phosphorus-based FRs |

| Piping | Polypropylene, polyethylene, HIPS | UV-stable and thermally stable bromine compounds |

| Wire & Cable Jacketing | Polymer jacketing materials | Magnesium hydroxide, brominated FRs |

| Roofing & Window | Roofing materials, windows | Reactive flame retardants with aliphatic bromine |

High temperature resistant thermoplastics like TPUs and CPVCs make siding, gutters, and lights stronger and safer from fire. Flame retardant coatings on concrete, wood, and steel make a shield. This shield slows down burning and helps stop fires from spreading. These uses help buildings follow fire safety rules and prevent fires.

Electronics need fire resistant materials to stop fires from starting. Makers put brominated flame retardants, like Tetrabromobisphenol A, in circuit boards and strong plastics. These chemicals help devices pass fire safety tests and make less smoke. As electronics get smaller, they get hotter, so fire resistant media are even more needed. Some states want to limit certain flame retardants, but keeping devices safe is still most important. TVs, laptops, and home appliances all use these materials to work safely.

Cars, trains, and planes use fire resistant and flame retardant media in many ways. Flame-retardant cables help send power and signals safely. These cables can take high heat, oil, and tough conditions. Flame-retardant tapes hold panels together and protect batteries and inside parts. They meet world fire safety rules and lower smoke and harmful fumes. These uses keep people and equipment safe, so stopping fires is a big goal in cars, planes, and trains.

Clothes and gear use both flame-retardant and fire resistant fabrics. Treated fabrics slow down flames, while inherent fire resistant fabrics protect for a long time. Rules like EN ISO 11612 and NFPA 701 make sure clothes pass hard tests for heat, fire, and strength. Fire resistant fabrics are used in firefighter suits, furniture, tents, and boat gear. Each use must fit the dangers of the job, and gear needs to be certified for full safety.

Factories and air filters need fire resistant media to work safely in tough places. Materials like PPS, P84, PTFE, and fiberglass trap dust and gases even when it is hot. These filters catch tiny bits and keep machines and people safe. New ideas like double-layer filters and nano-coatings make filters work better and last longer. Flame retardancy, checked by rules like UL94 V0, makes sure filters still work if there is a fire. In cars and HVAC systems, flame retardant filters give good filtering and fire safety, helping keep air clean and safe.

Picking the right fire retardant starts with knowing what it will touch. Every job needs something different. For example, tubing and gaskets in machines must follow strict fire rules. The UL 94V-0 rule says burning must stop in 10 seconds. It also says no burning drops can light cotton below. Car, plane, and robot makers use these rules to keep things safe.

| Factor | Description |

|---|---|

| Application Needs | Find out where and how the media will be used. |

| Chemical & Thermal Resistance | Pick materials that can take the heat and chemicals. |

| Regulatory Compliance | Make sure the media passes UL 94 or other fire rules. |

| Environmental Impact | Stay away from chemicals like PFAS and halogen flame retardants. |

| Material Thickness & Formulation | Check if thickness and additives meet the rules. |

| Industry Requirements | Use media that fits your industry’s fire safety needs. |

| Testing & Certification | Only use media that has been tested and certified. |

Fire safety rules tell us how to use flame retardant media. These rules help keep people and buildings safe. The most used rules are:

ASTM E84 – Checks how fast flames and smoke move on building stuff.

UL 94 – Rates plastics and foams for how fast they stop burning.

NFPA 701 – Tests how well fabrics and films resist fire.

FMVSS 302 – Sets fire rules for things inside cars.

| Standard | Focus Area | Application Industries | Key Details and Purpose |

|---|---|---|---|

| UL 94 | How plastic burns | Cars, planes, medical devices | Puts plastics in groups by how well they resist fire (V-0, V-1, V-2) |

| ASTM E84 | How flames and smoke spread | Building and construction | Measures how far flames and smoke go |

| NFPA 701 | How fabrics and films burn | Textiles, inside fabrics | Tests how small pieces burn |

| FMVSS 302 | Car inside materials | Cars | Sets fire rules for car parts inside |

Following these rules makes sure fire retardant media really protect against fire.

Picking good brands helps keep things safe from fire. FreshAirFilter.net gives advice and sells many tested products. Top brands are:

| Brand/Product | Material Type | Key Features | Relevant Standards |

|---|---|---|---|

| Kevlar® (Du Pont) | Para-aramid | Puts out its own flames, soft, strong | NFPA 701, ASTM E84, EN 469 |

| Nomex® (Du Pont) | Meta-aramid | Turns to carbon in heat, does not melt | EN 469, EN ISO 11611 |

| Twaron® (Acordis) | Para-aramid | Puts out flames, lasts long | NFPA 701 |

| Ceramic, Quartz, Glass Fiber | Inorganic fibers | Do not burn, used where fire risk is high | NFPA 701, ASTM E84 |

These brands follow tough fire rules and work for many jobs. FreshAirFilter.net can help you pick the best one for your needs.

Fire retardant and high temperature media both help stop fires, but each has good and bad points.

Flame retardant types, like halogen-free TPU, are safer for the earth and make less smoke. They are good for cables and electronics and pass UL94-V0 and other fire rules.

These materials fight wear and chemicals, but may not last long in very high heat.

High temperature media, like glass fiber TPU, can take more heat but may be harder to use or bend.

The big challenge is picking the right media for the danger. Flame retardant types are best for short flames. High temperature media are better for long, hot jobs.

Tip: Always make sure your media passes all fire rules and fits the job’s fire safety needs.

Flame retardant media help stop fires from spreading. High temperature resistant media can handle very hot conditions. Both types keep people and things safe in different ways. New research talks about materials like thermosensitive hydrogels. These make a film that protects, lowers smoke, and are better for the environment. Experts say you should pick media that fits the heat, dust, and safety needs of the job.

| Application Aspect | Expert Guidance Summary |

|---|---|

| Operating Temperature | Pick blends that match how hot it gets |

| Safety | Use flame-retardant media if there is fire danger |

| Consultation | Ask experts and test the dust before choosing |

Always use certified brands and follow safety rules to stay protected.

Flame retardant media use chemicals to slow or stop fire. High temperature resistant media can handle very hot heat and stay strong. Flame retardant types only protect for a short time. High temperature resistant types last longer when things get really hot.

Some flame retardant materials, like inherent fabrics, work after many uses. Treated fabrics might lose their protection after washing or lots of use. Always read the label to know how to care for them.

Some old flame retardant chemicals can hurt people and nature. Newer kinds are made to be safer. Always pick products that follow safety rules and do not have harmful chemicals.

Factories, power plants, planes, and cars need high temperature resistant materials. These places have parts that get very hot. Using the right material helps stop accidents and keeps people safe.

Check for labels or certificates like UL 94, NFPA 701, or ASTM E84. These mean the product passed fire safety tests. Trusted brands and sellers, like FreshAirFilter.net, give certified products.

content is empty!