Views: 0 Author: Site Editor Publish Time: 2025-07-16 Origin: Site

Top 5 applications for DPA Pocket Filters in 2025:

Spray and painting booths

Healthcare facilities

Commercial buildings

Industrial manufacturing

Educational institutions

Advanced filtration has become essential in modern industries as air quality impacts both health and operational efficiency. Demand rises due to strict regulations and rapid industrial growth, especially in regions like Asia Pacific. DPA Pocket Filter technology now features multi-pocket designs, low pressure drop, and customizable materials. These advancements deliver high efficiency, longer service life, and strong environmental responsibility.

DPA Pocket Filters improve air quality in diverse settings like spray booths, hospitals, offices, factories, and schools.

Their multi-pocket design increases surface area, capturing more particles and extending filter life.

These filters protect workers and equipment by trapping harmful dust, fumes, allergens, and microbes.

DPA Pocket Filters help facilities meet strict air quality and safety regulations in 2025.

Low pressure drop in these filters reduces energy use and lowers HVAC operating costs.

Regular maintenance and timely filter replacement keep air clean and systems efficient.

Customizable filter frames and materials ensure durability in harsh industrial environments.

Using DPA Pocket Filters supports healthier indoor environments, boosting safety, comfort, and productivity.

Spray and painting booths play a vital role in industries such as automotive, aerospace, and manufacturing. These environments require strict control of airborne particles and fumes to protect both workers and products. The DPA Pocket Filter stands out as a reliable solution for capturing paint mist and oil mist emissions.

Overspray occurs when paint particles miss their target and become airborne. These particles can settle on surfaces, causing defects and contamination. The DPA Pocket Filter uses advanced synthetic fiber media to trap these particles before they escape into the workspace or the environment. This filter features a multi-pocket design, which increases the surface area and dust holding capacity. As a result, it captures more overspray and extends the time between filter changes.

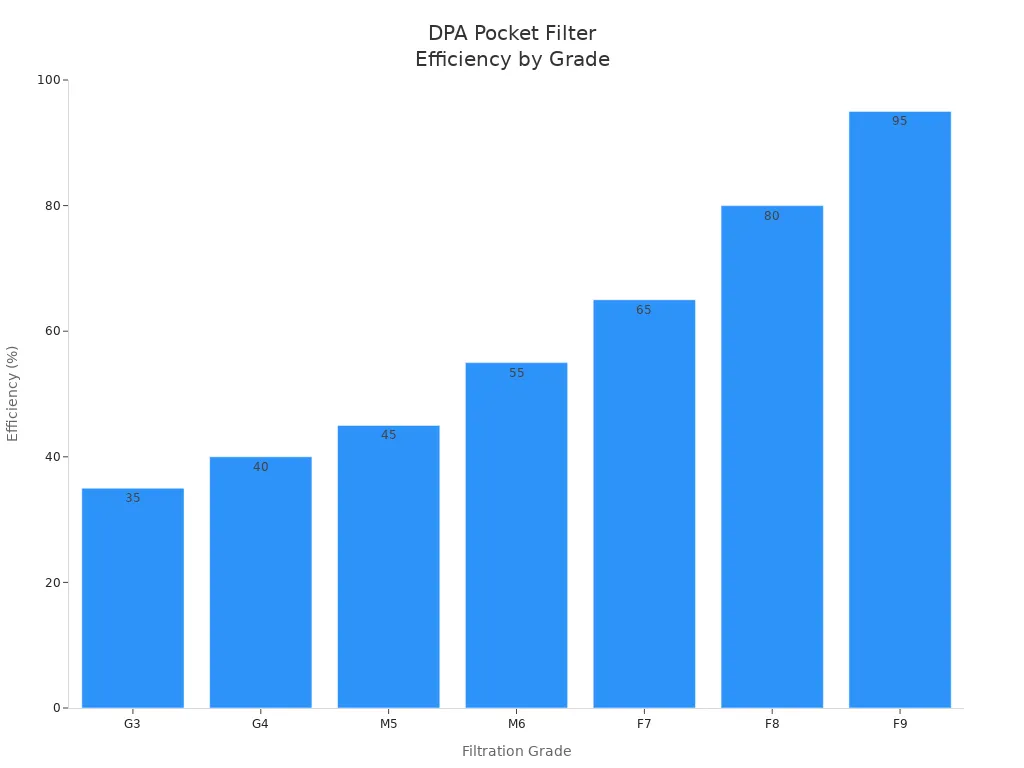

The following table shows the efficiency ratings of different filter grades used in spray booths:

| Filtration Grade | Efficiency Range (EN779) | Initial Resistance (Pa) | Rated Airflow (m³/h) | Filter Area (m²) |

|---|---|---|---|---|

| G3 | ~35% | 35 | 1700-3400 | 2.32-4.64 |

| G4 | ~40% | 40 | 1700-3400 | 2.32-4.64 |

| M5 | ~45% | 45 | 1700-3400 | 2.32-4.64 |

| M6 | ~55% | 55 | 1700-3400 | 2.32-4.64 |

| F7 | ~65% | 65 | 1700-3400 | 2.32-4.64 |

| F8 | ~80% | 80 | 1700-3400 | 2.32-4.64 |

| F9 | ~95% | 95 | 1700-3400 | 2.32-4.64 |

These filters meet both European DIN53438-F1 and American UL900-Class2 standards. Their low resistance and large filtration area help maintain steady airflow, which is essential for spray booth performance.

Clean air is crucial in spray booths. The DPA Pocket Filter removes fine particles and fumes, reducing the risk of dust contamination and paint defects. This leads to better product quality and fewer reworks. The filter’s high dust holding capacity also means less frequent maintenance, which saves time and money.

Spray booths contain hazardous chemicals and flammable materials. Proper filtration protects workers from inhaling harmful particles and fumes. The DPA Pocket Filter helps maintain a safe breathing environment by trapping airborne contaminants. This reduces health risks and supports a safer workplace.

Tip: Regular filter maintenance is important. Clean or replace filters as recommended to keep air quality high and protect workers.

Regulations for spray booths have become stricter in 2025. Authorities require effective ventilation, regular filter maintenance, and safe exhaust systems. Some key requirements include:

Airflow must move toward exhaust outlets to remove overspray and fumes.

Exhaust systems must expel hazardous fumes outside the workplace.

Filters and fans require regular maintenance.

Fans should be non-sparking to prevent ignition risks.

Electrical equipment and lighting must be explosion-proof.

Automatic sprinkler systems should be installed for fire suppression.

No-smoking policies must be strictly enforced within and around spray booths.

Poor filtration can lead to dust contamination, paint adhesion problems, foul odors, increased fire risk, and failed inspections. Using high-quality filters like the DPA Pocket Filter helps businesses meet these regulations, protect their reputation, and ensure safe operations.

Hospitals and clinics must keep their air clean to protect patients and staff. Airborne pathogens can spread quickly in these environments. DPA Pocket Filters help reduce this risk by capturing harmful particles before they circulate.

Certain hospital zones, such as operating rooms and intensive care units, require the highest level of air cleanliness. These areas often house patients with weakened immune systems. DPA Pocket Filters play a key role in maintaining sterile conditions. Their multi-pocket design increases the surface area for trapping dust, fungal spores, and other contaminants. This design helps prevent the spread of infections in critical spaces.

Tip: Regular filter checks and replacements ensure that critical areas remain safe for both patients and healthcare workers.

Patient safety depends on more than just clean surfaces. Air quality also matters. DPA Pocket Filters remove fine particles and microbes from the air. This reduces the chance of hospital-acquired infections. When filters work well, patients breathe cleaner air, which supports faster recovery and better health outcomes.

Healthcare facilities face several air quality challenges:

Dust can build up in ventilation systems.

Fungal spores and microbes may grow if filters are not changed on time.

Air leakage can allow contaminants to enter clean areas.

Proper air changes per hour (ACH) and pressure differences must be maintained.

Filters must be handled carefully during replacement to avoid spreading dust and spores.

DPA Pocket Filters address these issues by maintaining filter integrity and supporting optimal airflow. They help keep the air safe for everyone in the facility.

Hospitals must meet strict air quality standards. These rules set limits for dust, microbes, and other airborne particles. DPA Pocket Filters help facilities comply with these standards by providing high filtration efficiency and supporting proper ventilation.

A typical hospital HVAC system uses filters that must:

Remove dust and spores effectively.

Maintain required pressure differences between rooms.

Support airflow patterns that prevent cross-contamination.

Some facilities use portable HEPA units to boost filtration, aiming for more than 12 air changes per hour. DPA Pocket Filters work well with these systems, helping hospitals reach their air quality goals.

Clean air in healthcare settings protects patients, staff, and visitors. DPA Pocket Filters offer a reliable solution for infection control and regulatory compliance.

Commercial buildings, such as offices, shopping centers, and hotels, require clean air for the health and comfort of everyone inside. DPA Pocket Filters play a key role in maintaining high indoor air quality. These filters trap fine dust, allergens, and other airborne particles that can cause health problems or discomfort.

Healthy employees work better and take fewer sick days. DPA Pocket Filters help remove dust, pollen, and even very fine particles from the air. This reduces the risk of allergies and respiratory issues. Many commercial buildings use HVAC systems that circulate air throughout the space. If the air contains dust or other contaminants, people may experience headaches, fatigue, or irritation. DPA Pocket Filters use spunbonded polyester media with a conductive aluminized surface. This design helps dissipate static electricity and safely captures fine and potentially explosive dusts. The filters meet dust class 'M' according to EN 60335-2-69, which means they handle a wide range of dust types, including food flavorings, paint pigments, pharmaceutical powders, and toner.

Clean air supports better focus and comfort for everyone in the building.

Energy efficiency matters for building owners and managers. DPA Pocket Filters have a low pressure drop, which means HVAC systems do not need to work as hard to move air. This saves energy and lowers utility bills. The filters also last longer because of their large dust holding capacity. Fewer filter changes mean less waste and lower maintenance costs. Building managers can keep air clean and save money at the same time.

DPA Pocket Filters fit easily into most commercial HVAC systems. Their multi-pocket design increases the surface area for filtration, which improves performance without taking up extra space. The filters work well in systems that handle large volumes of air, such as those found in shopping malls, office towers, and hotels.

The following table highlights key features of DPA Pocket Filters used in commercial buildings:

| Feature/Aspect | Details |

|---|---|

| Filter Media | Spunbonded polyester with conductive aluminised surface for static dissipation |

| Certification | Dust class 'M' according to EN 60335-2-69 |

| Key Properties | Antistatic, suitable for very fine and potentially explosive dusts |

| Emission Reduction | Helps reduce emissions critical to processes |

| Types of Dust Handled | Flour, food flavorings, paint pigments, pharmaceutical powders, toner, wood, and more |

| Typical Applications | Bulk handling, packaging, powder paint coating, silo venting, tablet coating, weighing |

| Industries Served | Chemical, food & beverage, metalworking, pharmaceutical, woodworking |

Facility managers can rely on DPA Pocket Filters to keep air clean and systems running smoothly. These filters help commercial buildings meet air quality standards and provide a healthier environment for everyone inside.

Industrial manufacturing environments face many challenges with air quality. Factories and plants often generate a wide range of airborne contaminants. These particles can harm equipment, products, and workers. The DPA Pocket Filter provides a strong solution for these problems.

Manufacturers use many machines and processes that release dust, fumes, and mist into the air. The DPA Pocket Filter captures these particles before they spread. This filter uses a multi-pocket design to increase the area for trapping contaminants. It works well in both large and small industrial settings.

Machines in factories need clean air to work well. Dust and fine powders can enter motors, gears, and control panels. Over time, these particles cause wear and damage. The DPA Pocket Filter helps keep equipment safe by removing harmful particles from the air. Clean air reduces the risk of breakdowns and extends the life of machines.

Tip: Regular filter checks help prevent costly repairs and downtime.

Product quality depends on a clean environment. Fine dust, smoke, and fumes can settle on products during manufacturing. This can lead to defects or contamination. The DPA Pocket Filter traps these particles, helping companies produce high-quality goods. Clean air also supports better finishes on painted or coated items.

The table below shows common sources of airborne contaminants in industrial manufacturing:

| Airborne Contaminant Type | Description / Application Context |

|---|---|

| Smoke | Common in soldering and laser operations, captured by fume extractors |

| Dust | General industrial dust collection and cleaning |

| Solder Fumes | Extracted at benchtop soldering stations |

| Chemical Fumes and Vapors | Heavy chemical fumes and odors removed by multi-stage filtration |

| Toxic Media | Captured in toxic media handling and chemical workstations |

| Welding Fumes | Collected during welding processes |

| Coolant / Oil Mist | Present in metalworking and machining environments |

| Fine Powders | Generated in various manufacturing processes |

| Metalworking Chips / Fluids | Produced during machining and metalworking |

These contaminants can damage both products and equipment. The DPA Pocket Filter targets these particles to keep the workspace clean.

Some factories operate in harsh conditions. High temperatures, humidity, and chemical exposure can make filtration difficult. The DPA Pocket Filter uses durable materials that resist these challenges. It continues to perform well even in tough settings. Workers and managers can trust this filter to protect both people and machines.

Note: Choosing the right filter helps companies meet safety rules and improve workplace health.

Clean air in schools protects both students and staff. Many schools face challenges with indoor air quality. Poor air can lead to health problems and disrupt learning. DPA Pocket Filters help create a safer environment by removing harmful particles from the air.

Classrooms often have high occupancy and limited ventilation. This makes them hotspots for airborne pollutants. Students and teachers spend many hours in these rooms each day. Poor air quality can cause several health issues:

Respiratory illnesses such as asthma and bronchitis

Increased coughing, headaches, and breathing difficulties

Higher rates of absenteeism due to sickness

Cognitive and mental health impairments

Disrupted brain development in children, affecting memory and learning

DPA Pocket Filters trap fine particles like PM2.5, which include respiratory droplets that spread diseases such as COVID-19, influenza, and RSV. By filtering these particles, the filters help reduce the spread of illness and keep classrooms healthier. Cleaner air supports better focus and learning outcomes for students.

Tip: Schools near busy roads or airports face higher risks from outdoor air pollution. Using high-efficiency filters can make a big difference in these locations.

Hallways, cafeterias, and gyms see a lot of movement throughout the day. These spaces can collect dust, pollen, and volatile organic compounds (VOCs). Exposure to these pollutants can worsen asthma symptoms and trigger allergies. DPA Pocket Filters remove these contaminants, making shared spaces safer for everyone. Cleaner air in common areas also helps reduce the risk of disease transmission during busy periods.

Allergens such as pollen and dust are common in schools. These particles can cause sneezing, itchy eyes, and asthma attacks. DPA Pocket Filters use advanced synthetic media to capture allergens before they circulate. This helps students with allergies breathe easier and participate more fully in school activities.

Studies show that portable HEPA filters can reduce ultrafine particle concentrations in classrooms by about 70%. DPA Pocket Filters offer similar benefits when installed in school HVAC systems. They help lower indoor air pollution, especially in schools located near high-traffic areas. Additional steps, such as sealing gaps and managing doorways, can further improve air quality.

Clean air in schools supports healthy brain development and reduces the risk of psychiatric disorders. DPA Pocket Filters play a key role in creating a safe and supportive learning environment.

Each application for air filtration has its own set of challenges. Spray and painting booths need to control overspray and protect workers from harmful fumes. Healthcare facilities must keep the air free from germs and tiny particles to protect patients and staff. Commercial buildings focus on keeping indoor air clean for comfort and health, while also saving energy. Industrial manufacturing sites deal with dust, fumes, and mist that can damage machines and products. Educational institutions want to keep students and staff safe from allergens and airborne diseases.

The table below highlights the unique needs of each sector:

| Application | Main Challenge | Key Requirement |

|---|---|---|

| Spray & Painting Booths | Overspray, fumes | High particle capture |

| Healthcare Facilities | Infection control | Microbe and dust removal |

| Commercial Buildings | Indoor air quality, energy use | Fine dust filtration, low resistance |

| Industrial Manufacturing | Equipment/product protection | Durable, high-capacity filter |

| Educational Institutions | Student/staff health | Allergen and germ reduction |

Note: Each environment faces different air quality threats. The right filter must match the specific risks and needs of the space.

DPA Pocket Filters offer solutions that fit all these unique needs. The multi-pocket design increases the surface area, which helps trap more particles and extends filter life. In spray booths, this means better control of paint mist and safer air for workers. In hospitals, the filter helps stop the spread of germs and keeps critical areas clean. Offices and malls benefit from cleaner air and lower energy costs because the filter allows air to flow easily. Factories use these filters to protect machines and improve product quality, even in tough conditions. Schools see fewer allergens and germs in the air, which helps students stay healthy and focused.

Facility managers choose DPA Pocket Filters because they meet strict standards and work well in many settings. The filters handle different types of dust and fumes, from fine powders to larger particles. Their strong build means they last longer, even in harsh environments.

DPA Pocket Filters help organizations meet safety rules, improve air quality, and lower maintenance costs. They provide a reliable choice for many industries in 2025.

Guangdong Fresh Filter Co., Ltd. stands out as a trusted supplier in the air filtration industry. The company has built a strong reputation for delivering reliable and innovative filtration solutions. Their team includes experienced engineers and technical experts who understand the needs of different industries. GUANGDONG FRESH serves customers worldwide, offering products that meet strict international standards. They focus on quality, safety, and customer satisfaction.

Guangdong Fresh Filter Co., Ltd. designs its DPA Pocket Filters with advanced technology and attention to detail. Several features set these filters apart from others on the market:

The filter uses a diamond-shaped paint mist filter cotton design. This shape increases the filter area and boosts efficiency.

A high-density fiber layer improves the separation of paint mist from the air.

The multi-bag design expands the effective filtration area, allowing the filter to capture more particles.

Frames come in customizable options, such as galvanized steel or aluminum alloy. These materials resist corrosion and provide long-lasting stability.

Customers can choose the number of filter bags and frame configurations to fit their specific needs.

The filter achieves impressive capture rates: 100% for paint particles above 20 microns, 99.5% for particles above 10 microns, and 80% for particles above 5 microns. This performance classifies it as a medium efficiency filtration material.

Note: These features help GUANGDONG FRESH's filters deliver high performance and durability in demanding environments.

Guangdong Fresh Filter Co., Ltd. offers several advantages for businesses seeking reliable air filtration:

| Advantage | Description |

|---|---|

| Expertise | The company employs skilled engineers and filtration specialists. |

| Product Range | They provide a wide selection of filters for many industries and needs. |

| Customization | Customers can request filters tailored to their equipment and requirements. |

| Support | Fresh Filter offers technical support and guidance for installation and use. |

| Quality Assurance | All products meet international safety and performance standards. |

Facility managers and business owners trust GUANGDONG FRESH for their commitment to quality and customer service. The company’s DPA Pocket Filter solutions help organizations achieve cleaner air, meet regulations, and protect both people and equipment.

DPA Pocket Filter technology supports clean air in spray booths, healthcare facilities, commercial buildings, manufacturing plants, and schools. Each setting benefits from improved safety, product quality, and compliance. Facility managers should review their air quality needs for 2025. Trusted suppliers like Fresh Filter Co., Ltd. can help select the right solution for every environment.

A DPA Pocket Filter is an air filter with multiple pockets. Each pocket traps dust, mist, and other particles. The filter helps keep air clean in many places, such as factories, schools, and hospitals.

Most facilities should check filters every three months. Replacement depends on air quality and usage. High-dust areas may need more frequent changes. Regular checks help maintain clean air and system efficiency.

DPA Pocket Filters come in many sizes and frame types. Most HVAC systems can use them. Facility managers should check filter size and frame compatibility before installation.

DPA Pocket Filters improve air quality, protect equipment, and support health. They last longer than many standard filters. Their design helps reduce maintenance costs and energy use.

Yes, DPA Pocket Filters capture pollen, dust, and other allergens. Schools and offices use them to help reduce allergy symptoms and improve comfort for everyone.

DPA Pocket Filters meet strict standards for filtration. Many industries use them to comply with local and international air quality rules. Using these filters helps facilities pass inspections.

The filters have a low pressure drop. HVAC systems use less energy to move air through them. This design helps lower utility bills and supports green building goals.

Facility staff should inspect filters regularly. Cleaning or replacing filters on schedule prevents clogs. Keeping HVAC systems clean also helps filters last longer and work better.